ZX2 Thermal

Modulator

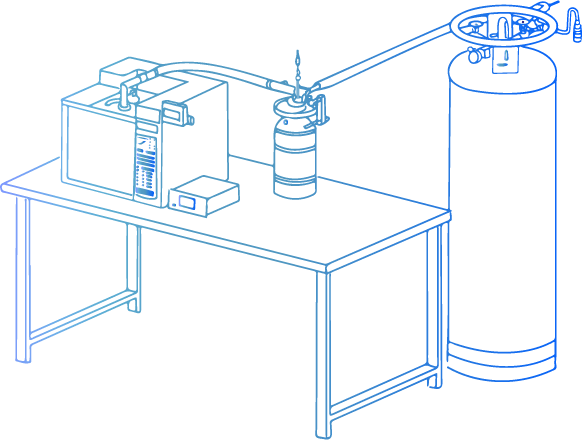

For applications requiring modulation across the n-C9+ carbon range, use the ZX2 system to eliminate consumable cryogens. A floor mounted refrigerator cools dry nitrogen gas to form the cold jet.

Note: as with the ZX1, admitting cold gas to the GC oven does not appreciably affect oven temperature.

(All necessary hoses are supplied, though not featured in diagrams.)

For applications requiring modulation across the n-C9+ carbon range, use the ZX2 system to eliminate consumable cryogens. A floor mounted refrigerator cools dry nitrogen gas to form the cold jet.

Note: as with the ZX1, admitting cold gas to the GC oven does not appreciably affect oven temperature.

(All necessary hoses are supplied, though not featured in diagrams.)

Features

• Consists of the following modules:

– Floor Chiller (no cryogenic

consumables)

– Programmable Logic Controller (PLC)

– Human-Machine Interface (HMI)

– Valve Assembly

– Top Plate Assembly

– Vacuum Insulated Transfer Line

– Head Clamp Assembly

• All cables, hoses, and assembly tools

are supplied.

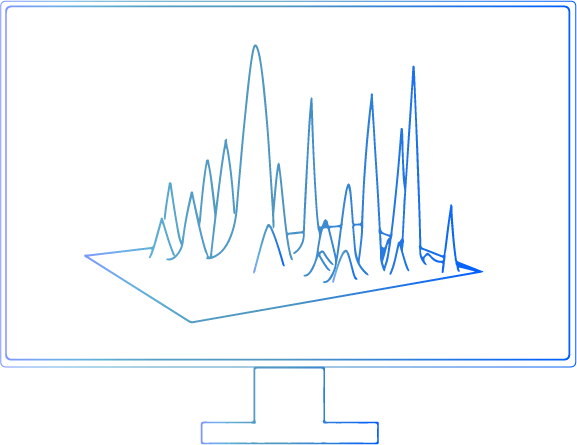

• Modulates nC9-nC30 routinely, and nC8

– nC45 with cold jet flow control*

* Contact Zoex for more information.

• Accommodates Two Parallel Column

Sets (“two modulators for the

price of one”).

• Compatible with most commercially

available GC systems.

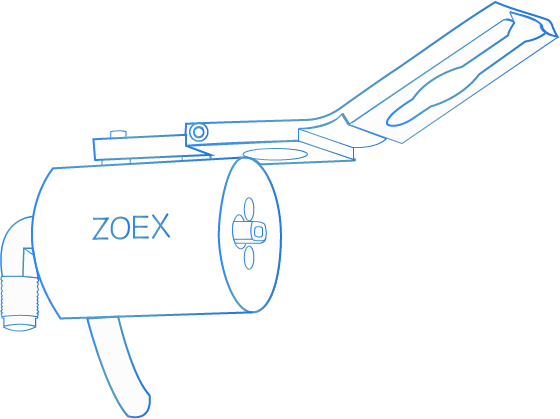

• No moving parts. High reliability.

• Open in-oven construction. No

modulation chamber.

• Effortless Modulator Tube Mounting.

• May be supplied turnkey with GC or

retrofitted onto user’s GC.

• Users can self-install the system in as

little as 2 hours.

Notice: Due to COVID-19 restrictions, user must install system in house. Installation requires approximately 1-2 hours. Detailed installation videos and phone support provided.

Specifications

GENERAL

| Two-stage loop modulation; one cold jet and one hot jet |

– |

| No moving parts | – |

| Hot Jet Temperature | Up to 450 °C |

| Cold Jet Temperature | As low as -90 °C |

| Hot Jet Pulse Duration | Set range: 0 to 32 secs 375 ms typical |

| Modulation Period | Set range: 0 to 32 secs Recommended: 3 to 32 secs Note: Set Modulation Period should be greater than the Hot Jet Pulse Duration |

| Jet Gas Consumption (Dry N2 or Air) |

25 SLM per jet max 10 to 15 SLM typical |

CRYOGENIC COOLING SYSTEM

| Continuous cooling without liquid nitrogen | – |

| Lowest cooling temperature | -90 °C (Measured 5 cm inside Cold Jet Nozzle) |

| SS vacuum insulated cryo transfer line | – |

| Floor Chiller Electrical | 120 V/60 Hz/11.5 A or 240 V/50 Hz/7.5 A |

| Floor Chiller Dimensions | 22”h x 15” w x 20.25”d (559 mm h x 381 mm w x 514 mm d) |

| Floor Chiller Weight | 170 lbs / 77 kg |