ZX1 Thermal

Modulator

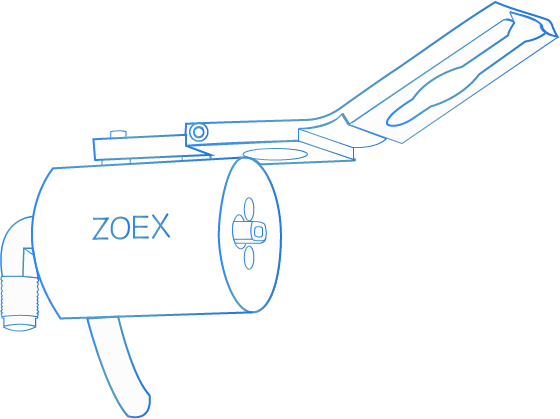

The ZX1 loop modulator has long held the world record for the number of organic molecular species separated in a single chromatographic analysis.

Capable of modulating all organic compounds amenable to gas chromatography, the ZX1 remains the unchallenged performance product in the GCxGC field.

* (All necessary hoses are supplied, though not featured in product overview video below.)

*Contact Zoex about modulating methane and ethane.

Click here to jump to features and specifications.

The ZX1 loop modulator has long held the world record for the number of organic molecular species separated in a single chromatographic analysis.

Capable of modulating all organic compounds amenable to gas chromatography, the ZX1 remains the unchallenged performance product in the GCxGC field.

*Contact Zoex about modulating methane and ethane.

(All necessary hoses are supplied, though not featured in diagrams.)

Features

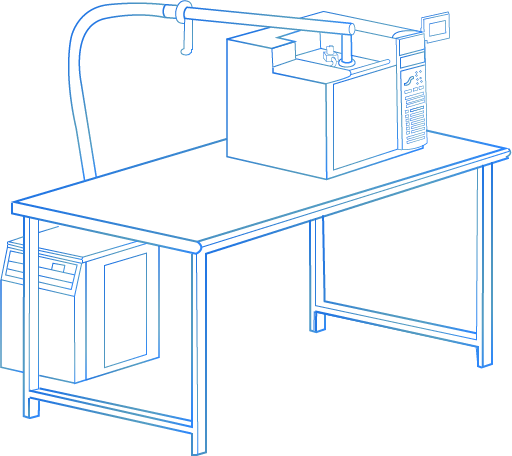

• Consists of the following modules:

– Floor Dewar*

– Bench Dewar

– Liquid Nitrogen Level Controller

– Programmable Logic Controller (PLC)

– Human-Machine Interface (HMI)

– Valve Assembly

– Top Plate Assembly

– Vacuum Insulated Transfer Line

– Head Clamp Assembly

• All cables, hoses, and assembly tools

are supplied.

• Modulates nC9-nC30 routinely, and nC8

– nC45 with cold jet flow control**

* User-supplied.

** Contact Zoex for more information.

• Accommodates Two Parallel Column

Sets (“two modulators for the

price of one”).

• Compatible with most commercially

available GC systems.

• No moving parts. High reliability.

• Open in-oven construction. No

modulation chamber.

• Effortless Modulator Tube Mounting.

• May be supplied turnkey with GC, or

retrofitted onto user’s GC.

• Users can self-install the system in as

little as 2 hours.

Notice: Due to COVID-19 restrictions, user must install system in house. Installation requires approximately 1-2 hours. Detailed installation videos and phone support provided.

Specifications

GENERAL

| Two-stage loop modulation; one cold jet and one hot jet |

– |

| No moving parts | – |

| Hot Jet Temperature | Up to 450 °C |

| Cold Jet Temperature | As low as -189 °C |

| Hot Jet Pulse Duration | Set range: 0 to 32 secs 375 ms typical |

| Modulation Period | Set range: 0 to 32 secs Recommended: 3 to 32 secs Note: Set Modulation Period should be greater thanthe Hot Jet Pulse Duration |

| Jet Gas Consumption (Dry N2 or Air) |

25 SLM per jet max 10 to 15 SLM typical |

CRYOGENIC COOLING SYSTEM

| Liquid nitrogen heat exchange bath | – |

| Lowest cooling temperature | -189 °C (Measured 5 cm inside Cold Jet Nozzle) |

| Flexible Vacuum Insulated Transfer Line | 36” (914 mm). Custom lengths available. |

| Bench Top Heat Exchange Dewar | 5 Liter, 24” h (610 mm) |

AUTOMATIC LIQUID NITROGEN LEVEL CONTROLLER

| Display | 4.3” 24-bit color TFT

display, 480 x 272 pixels Resistive touch screen |

| Dimensions | 3.8” h x 8.4” w x 11.4” d (97 mm h x 213 mm w x 279 mm d) |

| Weight | 3.3 lbs / 1.5 kg |

| Electrical | 100-240 ± 10% VAC, 50- 60 Hz, 2.2 A Max |