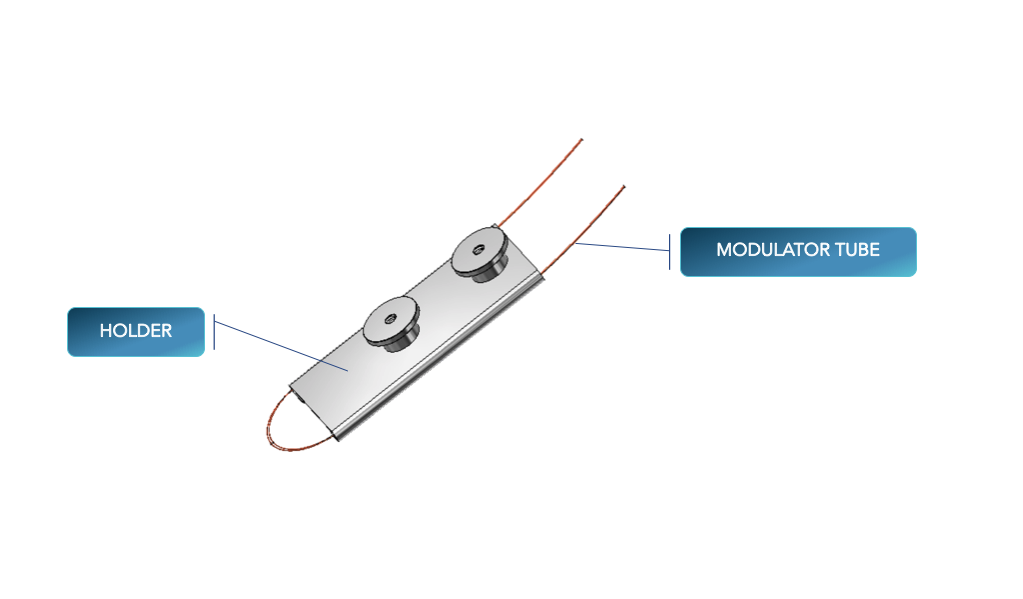

The Column Holder Assembly consists of a stainless steel “holder”, and the modulator tube, which is a length of capillary column, typically 1 meter long, wound inside the holder.

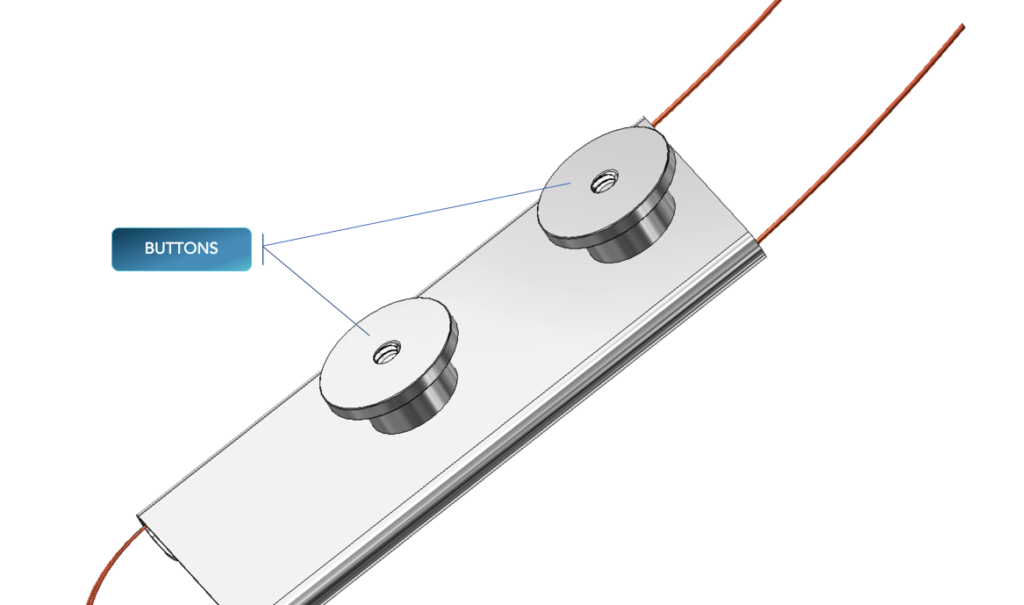

Two “buttons” on the column holder assembly insert into the “Head Clamp Assembly” to position the modulator tube.

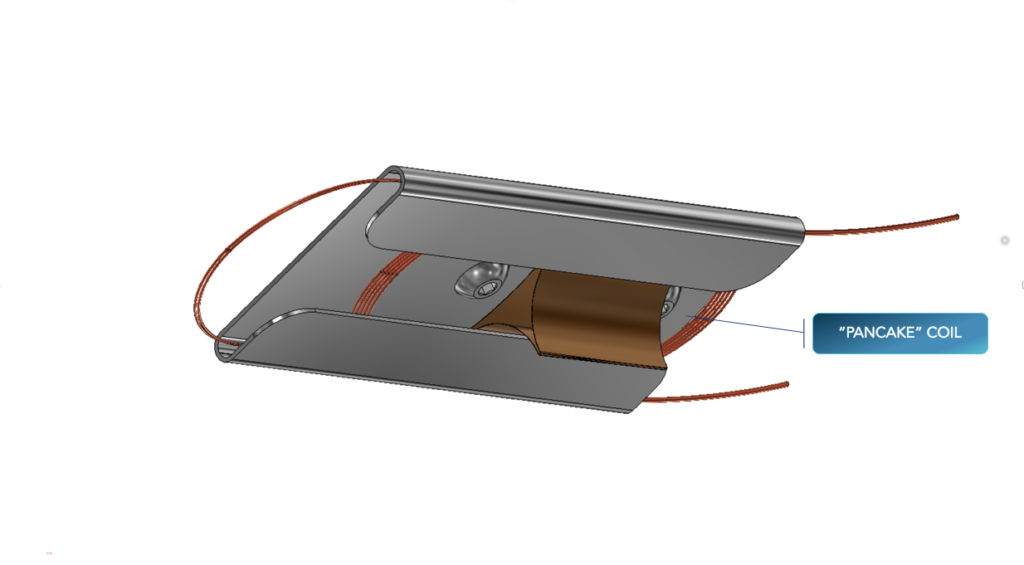

One meter of capillary column is wound by hand inside the column holder to form a race-track shaped “pancake” coil. The column winding procedure is easily performed in the field.

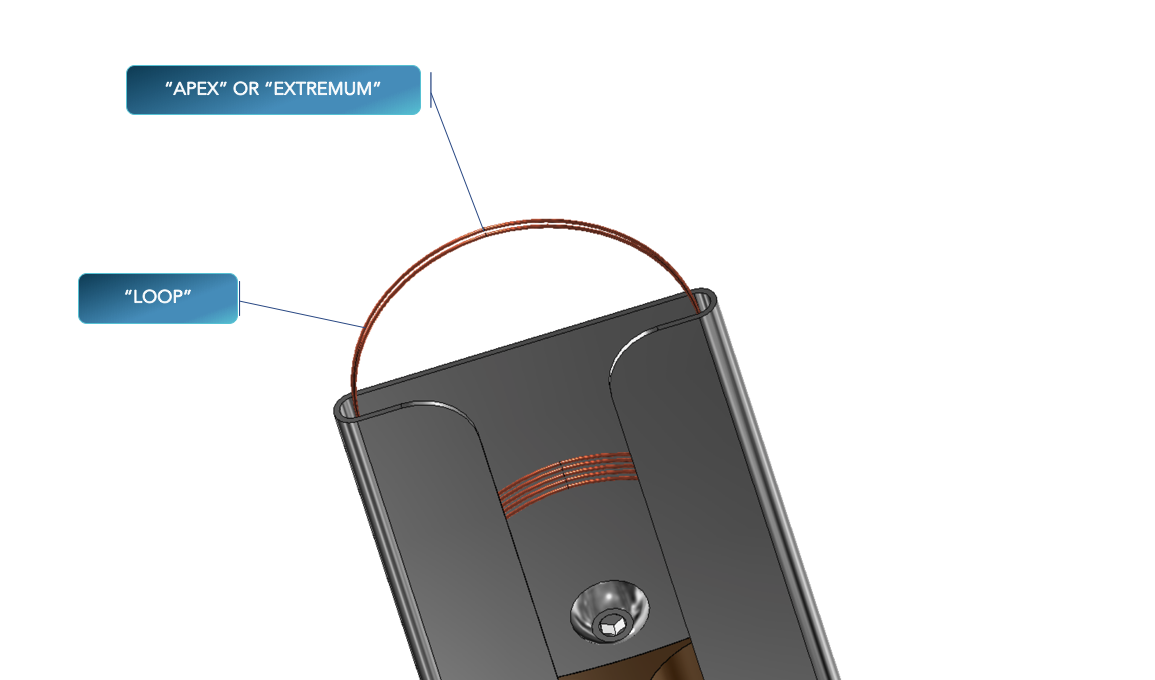

Two portions of the column protrude from one end of the column holder to form the “loop” structure. Note that the “loop” comprises not just one, but two, short runs of column material. Consequently, there are two cold spots, (typically one meter apart) along the length of the modulator tube. The cold spots are centered at the “apex” or “extremum” of the loop.

Periodic cooling and heating of these two cold spots, or modulator “stages” effects thermal modulation.

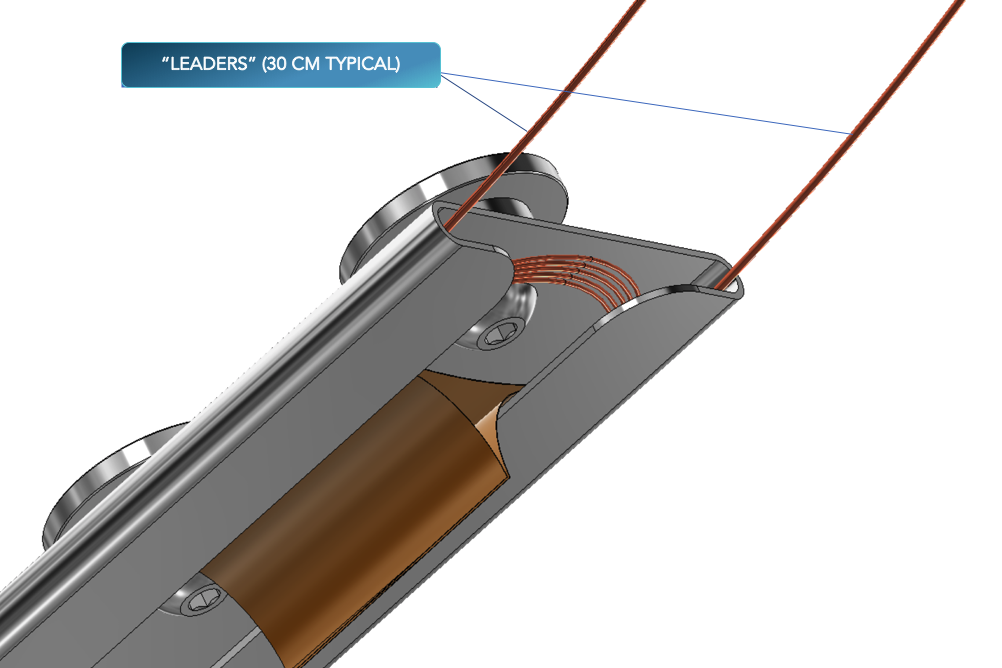

The “leaders” of the modulator tube connect to the primary and secondary columns of the GCxGC column set.

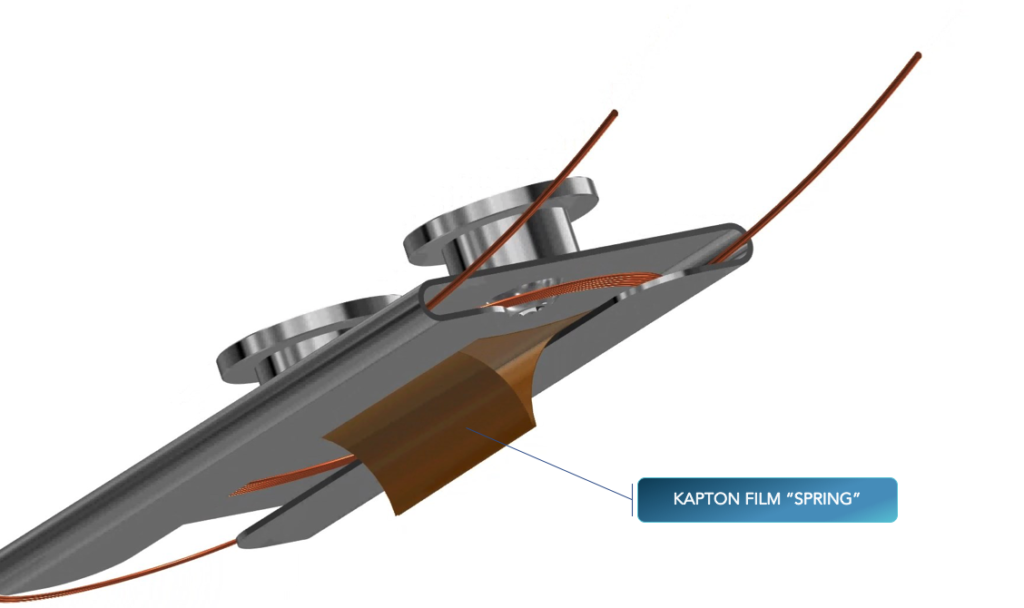

A folded Kapton film “spring”, inserted between the interior walls of the column holder locks the column windings into place, and allows the loop position to be adjusted for proper alignment with the hot and cold jets.

To learn more, contact Zoex: info@zoex.com